LCD splicing (liquid crystal splicing)

LCD liquid crystal display is the abbreviation of Liquid Crystal Display. The structure of LCD is to place liquid crystals between two parallel pieces of glass. There are many small vertical and horizontal wires between the two pieces of glass. The rod-shaped crystal molecules are controlled by whether or not electricity is applied. Change the direction to refract the light to produce the picture. The LCD consists of two glass plates, about 1 mm thick, separated by a uniform interval of 5 μm containing liquid crystal material. Because the liquid crystal material itself does not emit light, there are lamps on both sides of the display screen as the light source, and there is a backlight plate (or even light plate) and reflective film on the back of the liquid crystal display screen. The backlight plate is composed of fluorescent materials. Can emit light, its main function is to provide a uniform background light source.

The light emitted by the backlight plate enters the liquid crystal layer containing thousands of liquid crystal droplets after passing through the first polarizing filter layer. The droplets in the liquid crystal layer are all contained in a small cell structure, and one or more cells constitute a pixel on the screen. There are transparent electrodes between the glass plate and the liquid crystal material. The electrodes are divided into rows and columns. At the intersection of the rows and columns, the optical rotation state of the liquid crystal is changed by changing the voltage. The liquid crystal material acts like a small light valve. Around the liquid crystal material are the control circuit part and the drive circuit part. When the electrodes in the LCD generate an electric field, the liquid crystal molecules will be twisted, so that the light passing through it will be refracted regularly, and then filtered by the second layer of filter layer and displayed on the screen.

LCD splicing (liquid crystal splicing) is a new splicing technology that has emerged in recent years after DLP splicing and PDP splicing. LCD splicing walls have low power consumption, light weight, and long life (normally work for 50,000 hours) , Non-radiation, uniform picture brightness, etc., but its biggest disadvantage is that it cannot be seamlessly spliced, which is a little regrettable for industry users who require very fine display pictures. Since the LCD screen has a frame when it leaves the factory, a frame (seam) will appear when the LCD is spliced together. For example, the frame of a single 21-inch LCD screen is generally 6-10mm, and the seam between two LCD screens is 12- 20mm. In order to reduce the gap of LCD splicing, there are currently several methods in the industry. One is narrow-slit splicing and the other is micro-slit splicing. Micro-slit splicing means that the manufacturer removes the shell of the LCD screen that it has bought, and removes the glass and glass. However, this method is risky. If the LCD screen is not disassembled properly, it will damage the quality of the entire LCD screen. At present, very few domestic manufacturers use this method. In addition, after 2005, Samsung launched a special LCD screen for splicing-DID LCD screen. DID LCD screen is specially designed for splicing, and its frame is made small when leaving the factory.

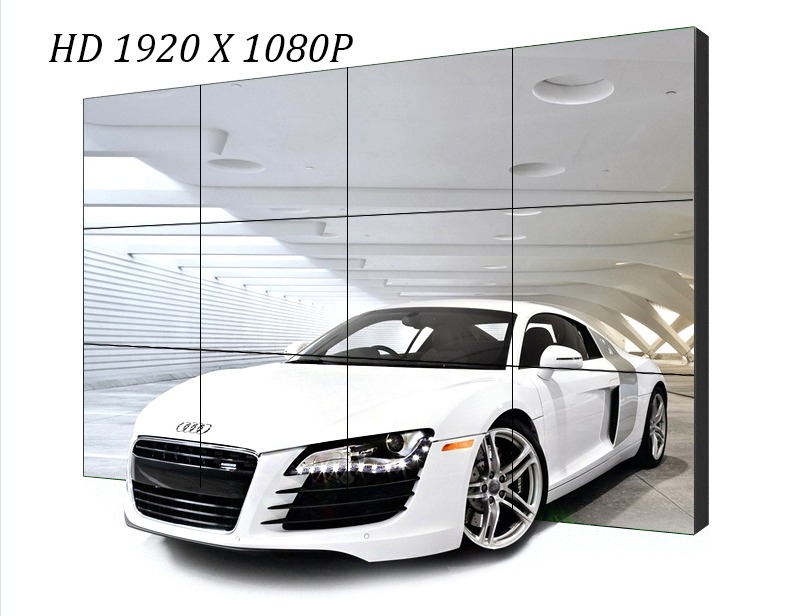

At present, the most common LCD sizes for LCD splicing walls are 19 inches, 20 inches, 40 inches, and 46 inches. It can be spliced at will according to customer needs, up to 10X10 splicing, using backlight to emit light, and its life span is as long as 50,000 hours. Secondly, the dot pitch of the LCD is small, and the physical resolution can easily reach the high-definition standard; in addition, the LCD screen has low power consumption and low heat generation. The power of a 40-inch LCD screen is only about 150W, which is only about 1/4 of that of plasma. , And stable operation, low maintenance cost.

Post time: Oct-27-2020